Machinery plays a crucial role in metal fabrication, and two commonly used tools in this field are the press brake and punch press. Both are essential in shaping and manipulating metal, yet they have distinctive differences in their operations, applications, and functionalities.

What Are the Key Differences Between Press Brake and Punch Press?

Press brakes bend metal with precision, while punch presses cut and form for high-speed mass production in metal fabrication.

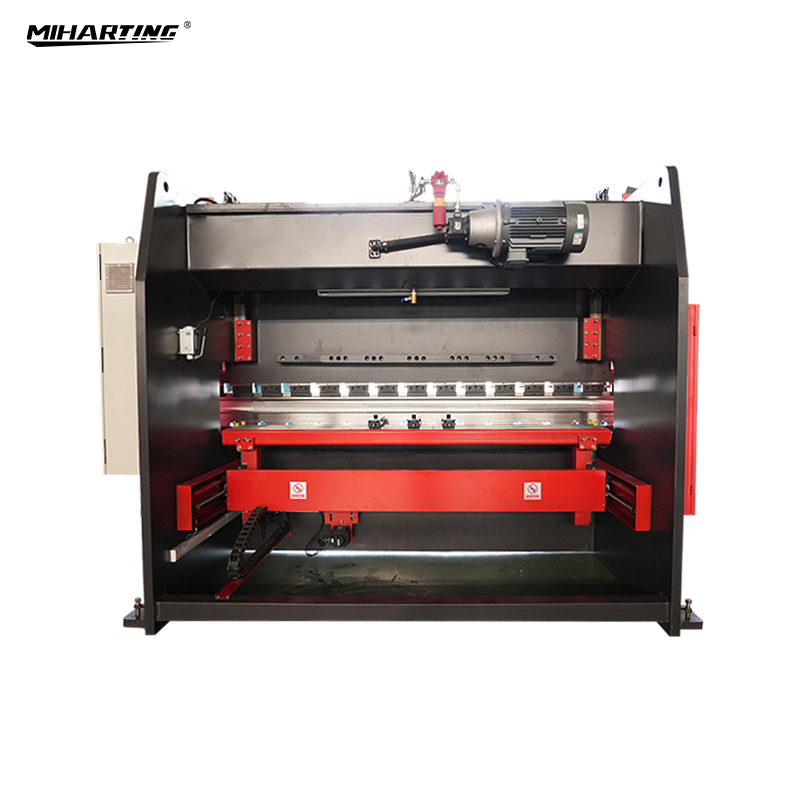

A press brake is a machine tool used for bending and shaping sheet metal. It typically consists of a hydraulic or mechanical press that operates by lowering a punch onto the material, which is positioned on a die. The bending force is applied gradually, allowing for precision and control over the metal's shape. Press brakes are highly versatile and commonly used for creating bends, angles, and various shapes in sheet metal.

Key Features of Press Brake:

- 1.Bending Capabilities: The primary function of a press brake is to bend metal sheets by exerting force along the material's length.

- 2.Precision and Flexibility: It offers high precision in bending and is capable of creating a wide range of shapes and angles.

- 3.Versatility: Press brakes can handle various materials, including aluminum, steel, and stainless steel.

A punch press, also known as a stamping press, is designed for cutting, stamping, or forming sheet metal by using a tool and die. It operates by vertically applying force through a tool (punch) onto the material against a die, resulting in the desired cut or shape. Punch presses are commonly utilized for mass production of consistent, repetitive metal components and products.

Key Features of Punch Press:

- 1.Cutting and Forming: The primary purpose of a punch press is to cut or form shapes on the metal sheet through force applied by the punch and die.

- 2.Mass Production: Ideal for mass production due to its ability to repeatedly create consistent shapes.

- 3.Speed and Efficiency: Punch presses are designed for high-speed operations, increasing efficiency in manufacturing processes.

Distinguishing Factors:

- 1.Function: The primary difference lies in their function. A press brake is primarily for bending metal, whereas a punch press is for cutting or forming shapes.

- 2.Operation: Press brakes work horizontally to bend sheet metal, while punch presses operate vertically for cutting or forming.

- 3.Applications: Press brakes are used for creating various angles and bends in metal sheets, especially in custom or low-volume production. Punch presses are more suited for high-volume, repetitive cutting, stamping, or forming tasks.

In summary, while both press brakes and punch presses are integral in metal fabrication, their distinctive functions, operations, and applications set them apart. Press brakes excel in bending and shaping metal sheets with precision and flexibility, while punch presses are geared towards cutting, stamping, and forming shapes at high speeds, particularly for mass production needs. Understanding the specific uses and capabilities of each machine is vital in optimizing their utilization within the metalworking industry.