As an experienced writer with over a decade of expertise in the domain of hydraulic shearing machines, I'm thrilled to share my knowledge and offer insights into this remarkable tool. This article will delve into the intricacies of hydraulic shearing machines, exploring their advantages, features, and offering practical tips for optimal performance.

Types of Hydraulic Shearing Machines

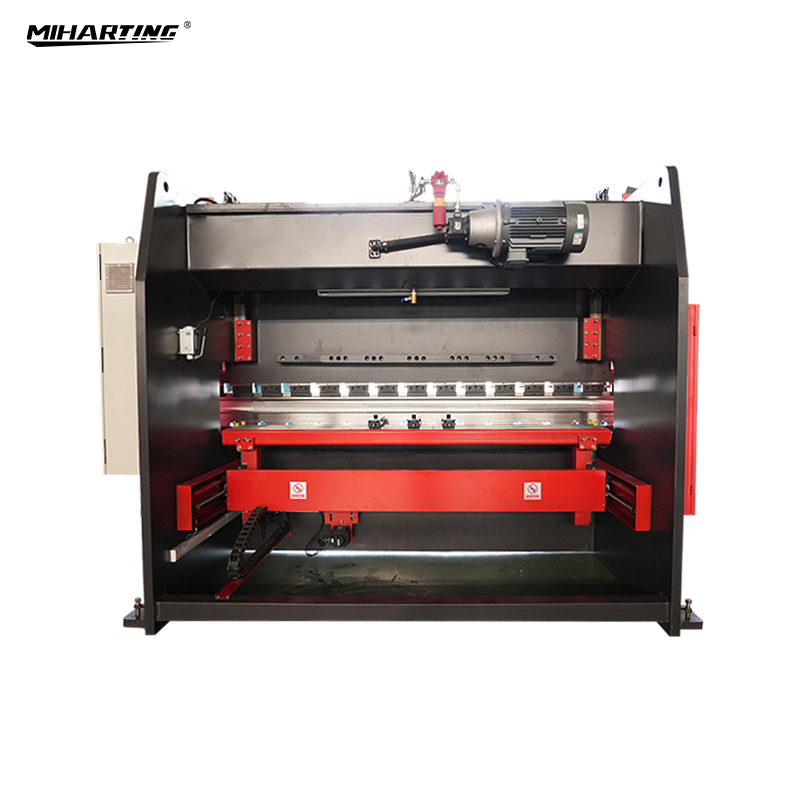

The world of hydraulic shearing machines encompasses a vast array of types, each tailored to specific applications.

- Guillotine Shear: This classic type resembles a guillotine, with a blade that descends vertically to cut through metal sheets.

- Swing Beam Shear: Unlike the guillotine shear, the swing beam shear features a blade that pivots on a hinge, providing a more precise cut.

- Plate Shear: Designed for heavy-duty applications, plate shears can cut through thick metal plates with ease.

Guillotine Shears: Versatile and Efficient

Guillotine shears have earned widespread popularity due to their versatility and efficiency. With cutting capacities ranging from thin sheets to thick plates, they cater to a wide spectrum of industries. Their robust construction ensures precise and reliable performance.

Swing Beam Shears: Precision and Control

Swing beam shears offer unparalleled precision, making them ideal for intricate cutting tasks. The pivoting blade allows for fine-tuning of the cut angle, ensuring a clean and accurate finish.

Plate Shears: Unparalleled Power and Capacity

Plate shears stand as the powerhouses of hydraulic shearing machines. Capable of slicing through thick metal plates with ease, they are indispensable in heavy industrial applications such as shipbuilding and construction.

Advantages of Hydraulic Shearing Machines

Hydraulic shearing machines stand out from their mechanical counterparts due to their numerous advantages:

- High Precision and Accuracy: The hydraulic system ensures precise control over the blade movement, resulting in accurate and consistent cuts.

- Reduced Noise and Vibration: Unlike mechanical shears, hydraulic machines operate quietly, minimizing noise pollution and creating a more comfortable work environment.

- Extended Blade Life: The smooth and controlled operation of hydraulic shears prolongs blade life, reducing maintenance costs.

Energy Efficiency and Durability

Hydraulic shearing machines are remarkably energy efficient, consuming less power than mechanical shears. Their robust construction and high-quality components ensure exceptional durability and longevity.

Safety and Ergonomics

Prioritizing safety, hydraulic shearing machines incorporate advanced safety features to protect operators. Ergonomic designs reduce fatigue and enhance productivity.

Features of Hydraulic Shearing Machines

Hydraulic shearing machines boast a range of features that enhance their performance and versatility:

- Variable Blade Gap Adjustment: The ability to adjust the blade gap allows for cutting materials of varying thicknesses.

- Automated Back Gauge: An automated back gauge ensures precise positioning of the material, facilitating accurate cuts.

- Programmable Controller: Advanced programmable controllers enable customization of cutting parameters, streamlining operations.

User-Friendly Controls

Hydraulic shearing machines are equipped with user-friendly controls, simplifying operation and minimizing training time. Intuitive interfaces allow operators to quickly set up and execute cutting programs.

Advanced Monitoring Systems

State-of-the-art monitoring systems provide real-time feedback on machine performance, enabling operators to identify and address any issues promptly.

Professional Tips Sharing

To maximize the efficiency and extend the lifespan of hydraulic shearing machines, consider the following tips:

- Regular Maintenance: Adhere to recommended maintenance schedules to ensure optimal performance and prevent breakdowns.

- Appropriate Blade Selection: Choose the right blade material and geometry for the specific material being cut.

- Optimal Cutting Parameters: Experiment with cutting parameters such as blade gap and cutting speed to achieve optimal results.

Troubleshooting and Problem-Solving

If you encounter any issues with your hydraulic shearing machine, consult the user manual or contact a qualified technician. Common problems include blade dulling, hydraulic leaks, and electrical malfunctions.

Applications in Diverse Industries

Hydraulic shearing machines find wide application in various industries:

- Automotive: Cutting sheet metal components for vehicles

- Construction: Fabrication of structural elements and roofing materials

- Aerospace: Precision cutting of aircraft components

- Electronics: Cutting circuit boards and other electronic components

Market Trends and Statistics

The global market for hydraulic shearing machines is projected to grow significantly in the coming years, driven by increasing demand in various industries.

- The market research firm Allied Market Research estimates the global hydraulic shearing machine market to reach $10.5 billion by 2027.

- The surge in infrastructure development and construction activities is a major contributor to this market growth.

- Developing regions, such as Asia-Pacific and South America, are expected to witness a surge in demand for hydraulic shearing machines.

Conclusion

The hydraulic shearing machine has established itself as an indispensable tool in metal fabrication and cutting industries. Its precision, efficiency, and versatility have transformed the way sheet metal is processed and cut. As the market continues to expand, manufacturers are constantly innovating to enhance the capabilities and performance of these machines. By understanding the advantages, features, and applications of hydraulic shearing machines, businesses can leverage this technology to increase productivity, improve accuracy, and drive profitability.