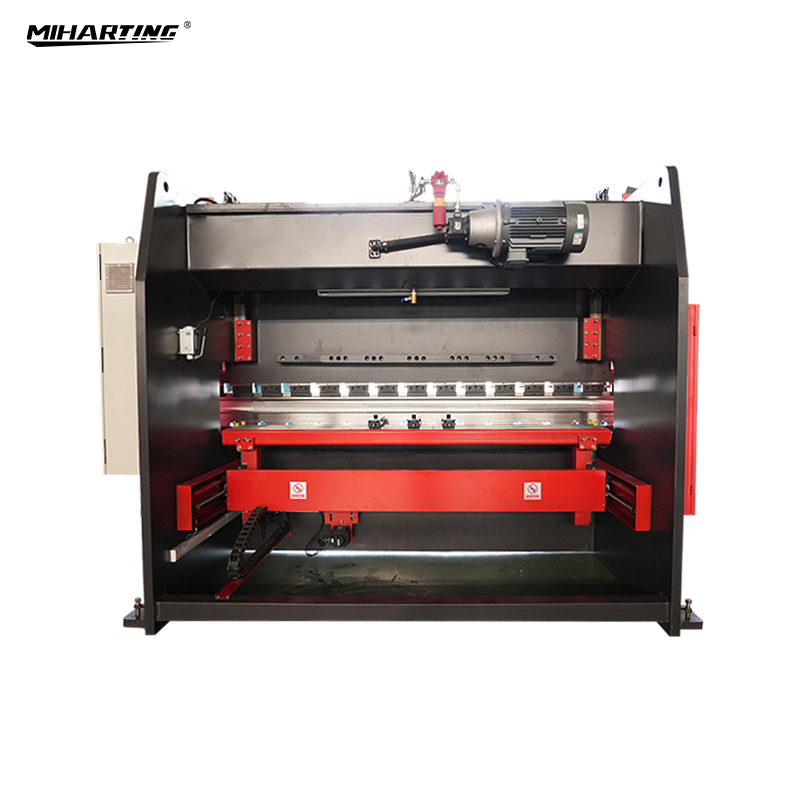

What is a Hydraulic Shearing Machine?

A hydraulic shearing machine is an industrial tool designed to cut sheets of metal into precise shapes and sizes. It employs hydraulic force to drive a blade that moves against a fixed blade, shearing the metal with unmatched precision.

Advantages of Hydraulic Shearing Machines

Hydraulic shearing machines offer numerous advantages over other cutting methods:

- High Precision: The hydraulic system ensures precise blade movement, resulting in clean and burr-free cuts with minimal distortions.

- Versatility: These machines can handle a wide range of materials, including steel, aluminum, and stainless steel, in various thicknesses.

- Efficiency: The hydraulic drive provides immense power, allowing for rapid cutting speeds and reduced downtime.

- Durability: Hydraulic shearing machines are built to withstand demanding industrial environments and offer extended service life.

- Safety: They are equipped with safety features such as blade guards and foot switches to minimize the risk of accidents.

Features of Hydraulic Shearing Machines

Typical features of hydraulic shearing machines include:

- Blade Gap Adjustment: Allows for fine-tuning the distance between the blades to accommodate different material thicknesses.

- Blade Angle Adjustment: Enables the blade angle to be optimized for specific materials and cutting requirements.

- Stroke Length Control: Adjusts the length of the blade stroke to suit the size and shape of the workpiece.

- Digital Readouts: Provide real-time information on blade position and cutting settings for increased accuracy.

- Hold-down Clamps: Secure the workpiece firmly during cutting, preventing movement or vibrations.

Types of Hydraulic Shearing Machines

Based on their construction and operation, hydraulic shearing machines can be categorized into:

- Guillotine Shears: Characterized by a straight, downward-moving blade that cuts the metal against a fixed bed.

- Swing Beam Shears: Feature a pivoted beam that swings the upper blade across the workpiece, providing greater versatility.

- Rotary Blade Shears: Utilize a rotating blade that trims the metal as it passes through the machine.

Applications of Hydraulic Shearing Machines

Hydraulic shearing machines find diverse applications in industries such as:

- Metal Fabrication: Creating custom parts and components for machinery, vehicles, and construction projects.

- Automotive Industry: Manufacturing body panels, chassis, and other automotive parts from sheet metal.

- Aerospace: Fabricating lightweight aircraft components with precision and accuracy.

- HVAC: Producing ductwork and other ventilation components from galvanized steel or aluminum sheets.

Tips for Using Hydraulic Shearing Machines

- Proper Maintenance: Regular lubrication, blade sharpening, and hydraulic fluid replacement are essential for optimal performance.

- Safe Operation: Always wear protective gear, follow proper procedures, and stay alert when operating the machine.

- Material Selection: Choose the appropriate blades and cutting parameters based on the material thickness and hardness.

- Blade Life Optimization: Adjust the blade gap, angle, and cutting stroke to minimize blade wear and extend their lifespan.

- Specialized Cutting Techniques: Explore advanced techniques like notching, louvering, and flanging to achieve complex cuts.

Common Problems and Troubleshooting

- Burrs on Cut Edges: Check for worn blades, improper blade gap, or excessive cutting speed.

- Blade Misalignment: Adjust the blade angle or gap to ensure proper alignment and reduce vibration.

- Uneven Cuts: Inspect the blade sharpness, ensure proper hold-down pressure, and check the workpiece for flatness.

- Hydraulic Leaks: Locate the leak, tighten connections, or replace seals as necessary.

- Electrical Faults: Check the wiring, electrical components, and contact a qualified electrician for repairs.

Environmental Benefits

Hydraulic shearing machines can contribute to environmental sustainability by:

- Reducing Waste: Precise cuts minimize scrap and reduce material wastage.

- Energy Efficiency: Modern machines feature energy-saving technologies, such as variable speed drives and regenerative braking.

- Improved Material Utilization: Optimized cutting parameters reduce the need for oversizing materials, saving resources and minimizing environmental impact.

Market Trends and Future Prospects

The hydraulic shearing machine market is expected to experience steady growth in the coming years due to:

- Increasing demand for precision cutting in various industries

- Technological advancements and automation

- Growing awareness of environmental sustainability

- Global infrastructure development projects

Conclusion

Hydraulic shearing machines are versatile and essential tools in the metalworking industry. Their ability to deliver precision cuts, handle diverse materials, and offer long service life makes them indispensable for a wide range of applications. By following best practices, addressing common issues effectively, and staying abreast of market trends, users can maximize the productivity, efficiency, and safety of their hydraulic shearing operations.