In modern manufacturing, metal processing is a vital part, and the bending machine, as an indispensable tool in this process, provides precise solutions for the forming and processing of various metal sheets.

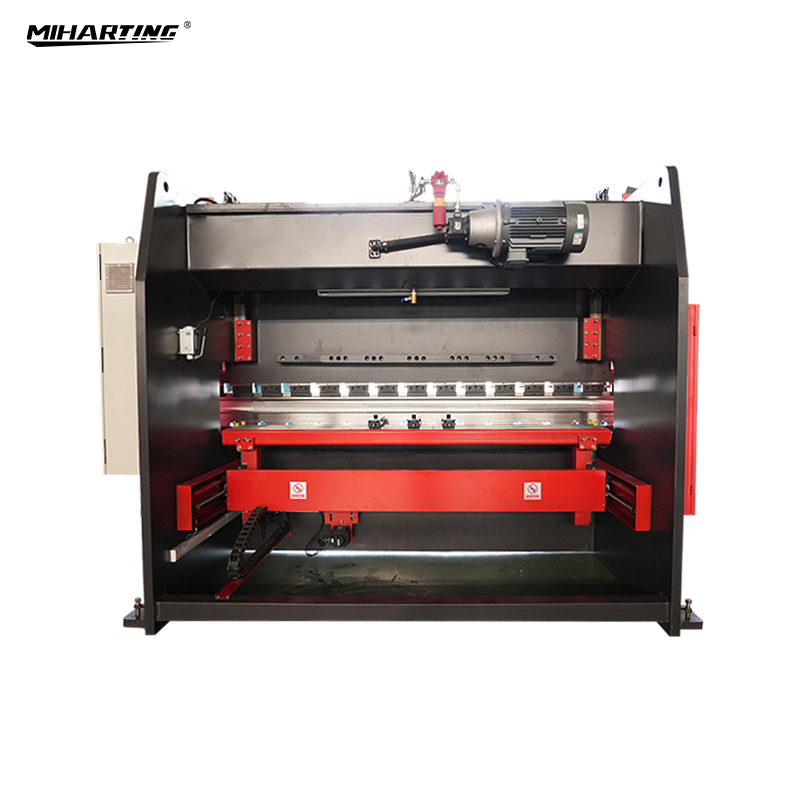

The main function of the bending machine is to bend the metal sheet into the desired shape by applying pressure. This process usually involves placing the sheet between the dies and processing it through the squeezing or bending action of the upper and lower dies. The bending machine can not only accurately control the bending angle, but also handle metal sheets of different thicknesses and materials to meet various complex processing requirements.

Mechanical bending machines are usually operated using a mechanical transmission system and are suitable for small and medium-sized production tasks. Its advantages are simple structure and low maintenance cost, but it is slightly inferior to CNC bending machines in accuracy and efficiency. Hydraulic bending machines use hydraulic systems to apply pressure, have higher processing capacity and better bending accuracy. It is able to handle thicker metal sheets and is suitable for large-scale production and heavy processing.

Before operating the bending machine, the metal sheet needs to be prepared first. Make sure that the surface of the material is clean and free of oil or impurities, which helps to ensure the quality of the bending. Choose the appropriate die according to the different sheet thickness and hardness to ensure that there is no excessive wear or deformation during the bending process.

Correctly setting the operating parameters of the bending machine is the key to ensuring processing accuracy. This includes bending angle, spring back compensation, bending radius, etc. Spring back compensation is used to compensate for the possible spring back of the metal after bending, so as to ensure that the final product meets the design specifications.

Adjust the mold position of the bending machine according to the size and requirements of the work piece. Ensure that the contact surface between the upper and lower molds is uniform to avoid processing defects caused by excessive local stress. Regularly check and maintain the mold, and replace or trim it when necessary to maintain processing accuracy and equipment performance.

When operating the bending machine, it is recommended to perform a no-load test run first to check the settings and equipment status. Before formal processing, ensure that the plate is placed correctly and start the equipment for bending. Maintain a stable speed during operation to avoid processing errors caused by too fast or too slow operation.

When operating a bending machine, safety is the most important consideration. Wear appropriate safety protection equipment, such as protective glasses and gloves, and ensure that the working area is clean and free of obstacles. Regularly maintain and service the equipment, and check the operating status of the hydraulic system, transmission system, and electrical system to prevent safety accidents caused by equipment failure.

Bending machines are widely used in many industries. They are used to produce body parts in the automotive industry, to manufacture various metal structural parts in the construction industry, and to process high-precision aviation parts in the aerospace field. In addition, bending machines also play an important role in home appliances, shipbuilding, steel structure engineering and other fields.

As a key equipment in metal processing, high-quality bending machines occupy an important position in modern manufacturing due to their efficient and precise bending capabilities. By mastering the functions, operating skills and application fields of the bending machine, manufacturing companies can better utilize this equipment and achieve high-quality production goals. With the continuous advancement of technology, bending machines will continue to provide strong support and guarantee for the development of various industries.