CNC sheet metal bending machines are integral tools in the manufacturing industry, offering precise and efficient bending capabilities for a wide range of metal materials. These machines are essential for creating various components used in industries such as automotive, aerospace, construction, and more. In this article, we will explore the features, types, and benefits of CNC sheet metal bending machines, as well as their availability in the market.

Features of CNC Sheet Metal Bending Machines

CNC sheet metal bending machines are equipped with advanced features that enable them to accurately bend metal sheets according to specific requirements. These machines utilize computer numerical control (CNC) technology, allowing for automated operation and precise control over the bending process. With CNC systems, operators can program the machine to perform complex bending sequences, ensuring consistent and accurate results.

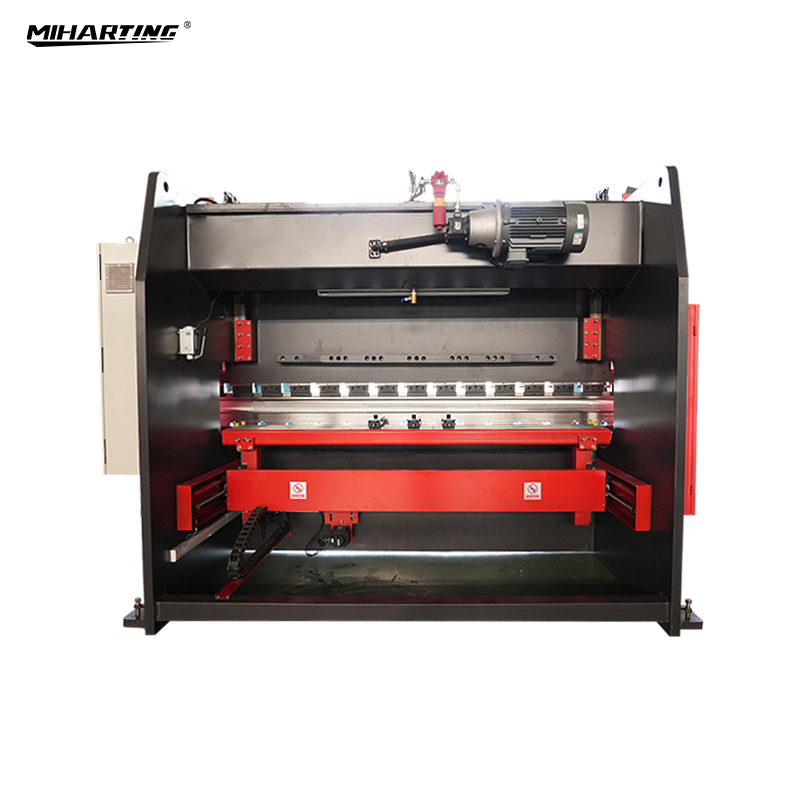

In addition, modern CNC sheet metal bending machines are designed with high-precision linear guides, servo-driven hydraulic systems, and user-friendly interfaces, enhancing their overall performance and usability. These features contribute to the efficiency and reliability of the bending process, making CNC sheet metal bending machines indispensable in metal fabrication operations.

Types of CNC Sheet Metal Bending Machines

There are several types of CNC sheet metal bending machines available in the market, each catering to specific bending requirements. One common type is the CNC sheet metal folding machine, which utilizes a folding beam to bend the metal sheet along a linear axis. This type of machine is ideal for producing simple bends and flanges in sheet metal components.

Another popular type is the CNC sheet metal bender machine, which employs a press brake to perform precise bending operations. Press brakes are capable of producing a wide range of bend angles and shapes, making them suitable for diverse metal bending applications.

Availability and Pricing

CNC sheet metal bending machines are widely available for purchase from various manufacturers and distributors. These machines come in different sizes, capacities, and configurations to accommodate the specific needs of metal fabrication facilities. When considering the purchase of a CNC sheet metal bending machine, factors such as bending capacity, precision, and automation capabilities should be taken into account.

As for pricing, the cost of CNC sheet metal bending machines varies depending on factors such as size, complexity, and technological features. While these machines represent a significant investment, their ability to enhance productivity, quality, and flexibility in metal bending operations makes them a worthwhile asset for manufacturing businesses.

In conclusion, CNC sheet metal bending machines play a crucial role in the metal fabrication industry, offering advanced capabilities for bending a variety of metal materials with precision and efficiency. With their advanced features, diverse types, and availability in the market, CNC sheet metal bending machines are essential tools for meeting the bending needs of modern manufacturing operations.