FEATURES

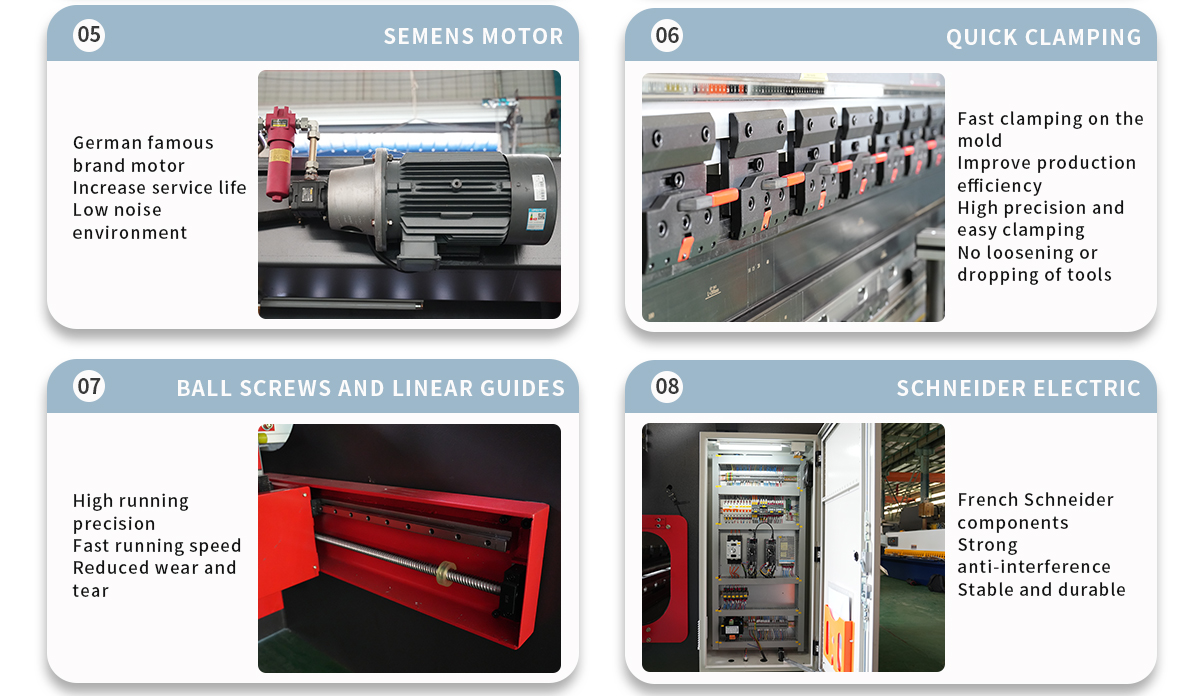

1.Press Brake Machine Hydraulic Power System

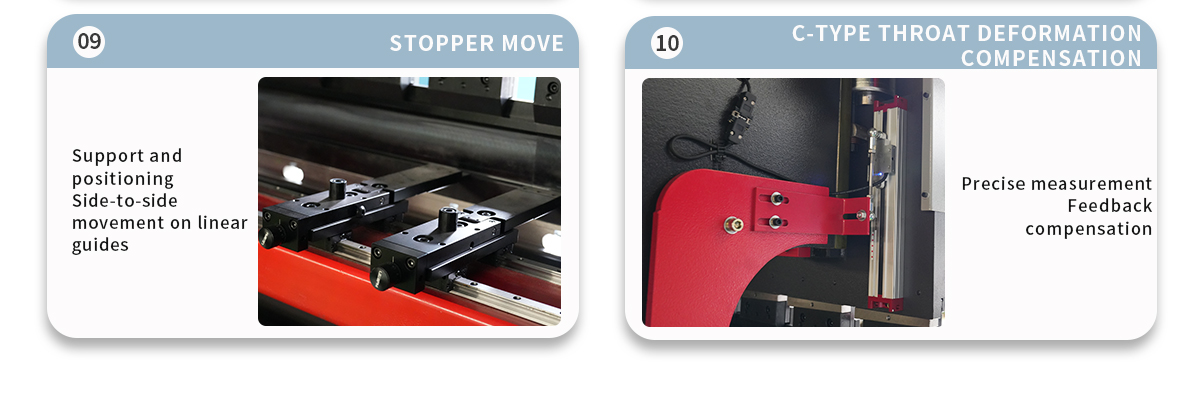

● A hydraulic pump is used to convert mechanical energy into hydraulic energy to drive dual oil cylinders. High-precision control is achieved through electro-hydraulic servo synchronization technology.

It is combined with a grating ruler to form a closed-loop control, and the synchronization accuracy can reach ±0.01mm.

● Equipped with a mechanical stop structure and deflection compensation system to automatically adjust the deformation of the slider to ensure bending straightness and angle accuracy.

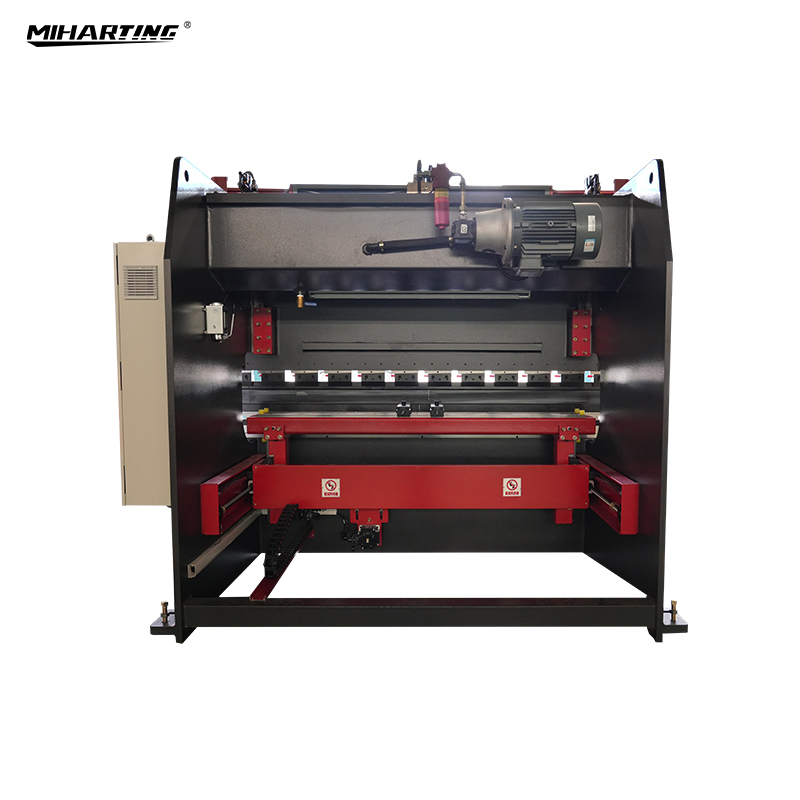

2.Structural design

● The all-steel welded fuselage has high strength and deformation resistance, supporting large-tonnage bending requirements (such as 100T and above).

● Modular mold design supports rapid replacement of molds to adapt to different workpiece shapes.

3.Intelligent control

● The CNC system supports multi-axis back gauge positioning (can be expanded to 8-12 axes), and integrates automatic programming, bending simulation and collision detection functions.

● Optional pressure sensor and remote diagnosis function can realize real-time monitoring of processing parameters.

CNC CONTROL SYSTEM

•"Shortcut" touch navigation. 10.1" high-definition TFT display •Multiple 4-axis control •Deflection compensation control •With mold/material/product library •Support servo or frequency conversion control •Advanced X-axis control method can control both loop adjustment and open-loop false adjustment. •Network dual-machine linkage (optional) •USB peripheral interface

•2D touch graphics programming •15° high resolution TFT true color display •Bending process planning •Disturbance compensation control •Servo and inverter control modes •Advanced Y-axis control algorithm can control both closed-loop and open-loop. • USB port

•2D touch graphics programming •3D product graphic simulation display •17" high resolution TFT true color display • COMPLETE WINDOWS APPLICATION PACKAGE •Compatible with DELEM modular structure system •USB, peripheral interface •User program application in multi-tasking environment •Angle detection sensor interface

•2D and 3D touch graphics programming •30 product graphic simulation displays •17° high resolution TFT true color display •Compatible with DELEM modular structure system •USB, peripheral interface. •User program application in multi-tasking environment •Angle detection sensor interface

• Back gauge control • Control universal motors or inverters • Pressure holding and unloading time setting • Work piece count • Stores 40 programs with 25 steps each • Promotional features

•Backgauge control •Control regular motors or inverters •Pressure holding and unloading time setting •Work piece count •Store 40 programs with 25 steps each •Preferential features

| Type( WE67K series) | Nominal Force (KN) | Bending Length (mm) | Poles distance(mm) | Throat Depth(mm) | Slider Travel(mm) | Die Loading Height(mm) | Main Motor Power(kw) | Axes | Compensation cylinders |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 4+1 | 2 |

| 80T/3200 | 800 | 3200 | 2700 | 350 | 170 | 380 | 7.5 | 4+1 | 3 |

| 100T/3200 | 100 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | 4+1 | 3 |

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | 4+1 | 3 |

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 320T/3200 | 3200 | 3200 | 2700 | 400 | 200 | 420 | 22 | 4+1 | 3 |

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 30 | 4+1 | Mechanical |

| 500T/5000 | 5000 | 5000 | 3900 | 500 | 320 | 600 | 37 | 4+1 | Mechanical |

| 600t/5000 | 6000 | 5000 | 3900 | 500 | 320 | 600 | 45 | 4+1 | Mechanical |