| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 |

| Punching Pressure ( T ) | 60T | 100T | 120T |

| Max.cutting thickness of steel plates(mm) | 16 | 20 | 25 |

| Material strength (N/mm2) | ≤450 | ≤450 | ≤450 |

| Angle of Shear (º) | 7º | 8º | 8º |

| Flat bar shearing (T × W)( mm ) | 16*250 8*400 | 20*330 10*480 | 16*250 8*400 |

| Max.length of cylinder stroke (m m) | 80 | 80 | 80 |

| Trips frequency (times/min) | 11-20 | 12-20 | 8-18 |

| Depth of throat (mm) | 300 | 355 | 400 |

| Punch depth (mm) | 16 | 20 | 25 |

| Max. punching diameter(mm) | 28 | 33 | 35 |

| Motor Power ( KW ) | 5.5 | 7.5 | 11 |

| Overall dimensions (L× W × H)(m m) | 1780*920*1780 | 1950*920*1950 | 2355*1000*2150 |

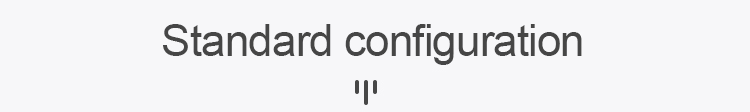

Product features:

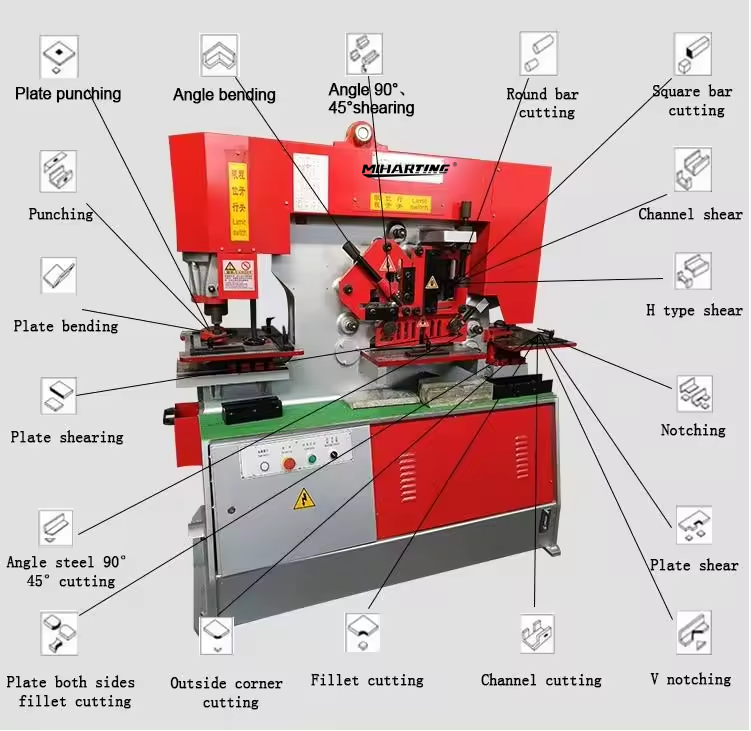

1. All the electrical parts are IMPORT with CE certificate.

2. Professionally engineered design frame structures.

3. Steel welds with high precision strength and rigidity to eliminate vibrations.

4. Ironworker steel frame Q235 = American standard steel A306 GR55.

5. Five sets of punch and blades were installed on the machine.

6. Timer relay by Japanese OMRON.

7. All wiring terminal block by WEIDMULLER.

8. Main Electrical component by Germany Schneider.

9. Oil seals by Japanese, NOK.

10. O-Ring and Valve by Taiwan for piston pump more durable.

11. Hydraulic System by Japanese Yuken.

12. Motor by Chinese Jiangsu Dazhong

13. Hydraulic fuel tanks and ironworker frame built by our Factory.

14. Dual independent hydraulic cylinder

15. Dual Footswitch controlled work separately

16. Easy Adjustable stroke control with ruler

17. Indicator on both hydraulic cylinders

18. Electric back gauge auto stop

19. Moveable working light that can be placed at any desired position

20. Hydraulic system with overload protection system

21. Emergency safety stop switch

22. Large punching table with ruler guide

23. Larger notching table with Ruler guide

24. Large flat shearing table with Ruler guide

25. Most important easy maintenance