FEATURES

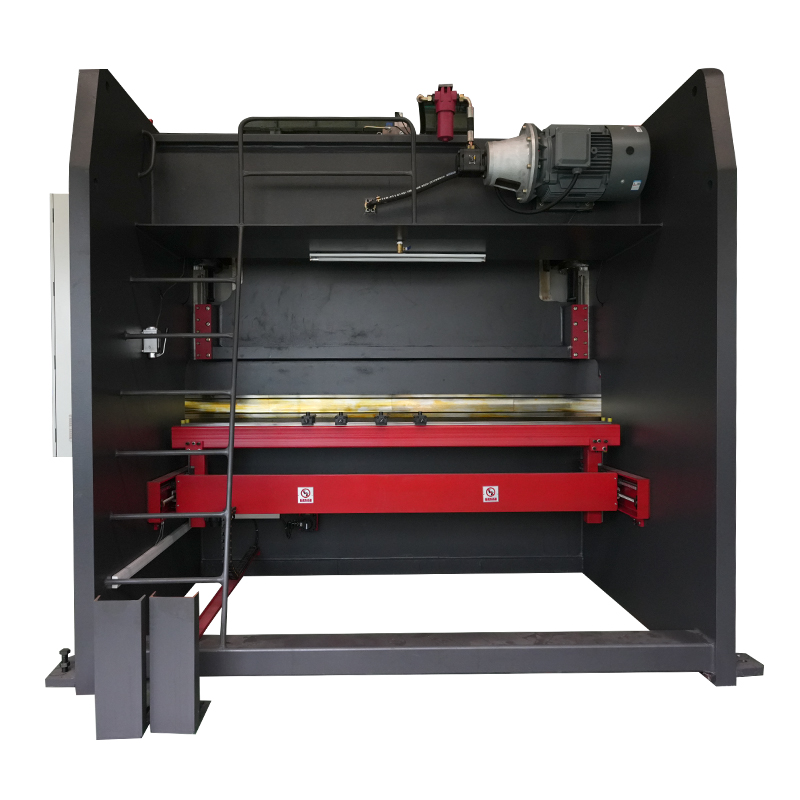

- OVERALL WELDED AND PROCESSED STRUCTURE, THE FRAME IS ANALYZED USING ANSYS FINITE ELEMENT ANALYSIS SOFTWARE TO ENSURE THE RELIABILIT OF THE MACHINE AND THE PRECISION OF THE MACHINE.

- ELECTRIC HYDRAULIC PROPORTIONAL SERVO SYNCHRONIZATION, ENSURING REPEATED ACCURACY.

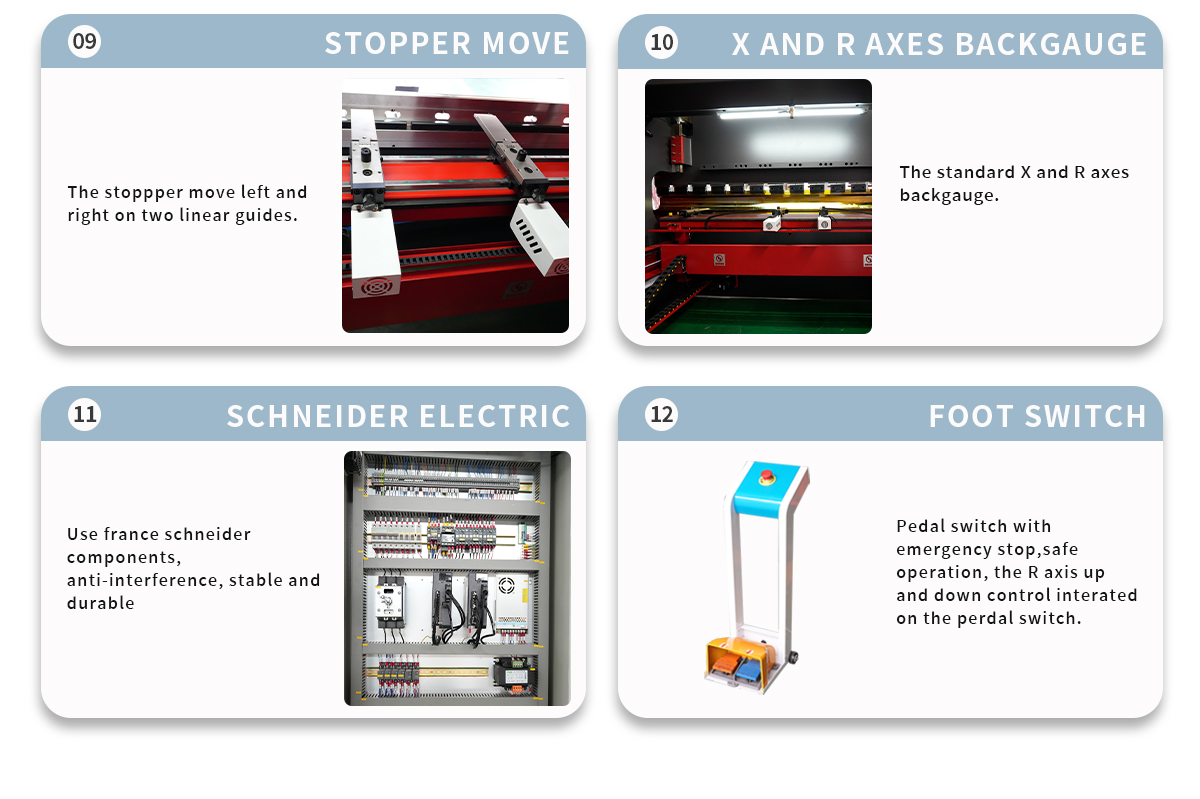

- THE STANDARD 4+1 AXES, IMPORTED BALL SCREW AND LINEAR GUIDE RAIL ENSURE THE SPEED AND ACCURACY OF THE BACKGAUGE, AND MORE MULTI-AXES BACKGAUGE MECHANISM CAN BE USED ACCORDING TO CUSTOMER REQUIREMENTS.

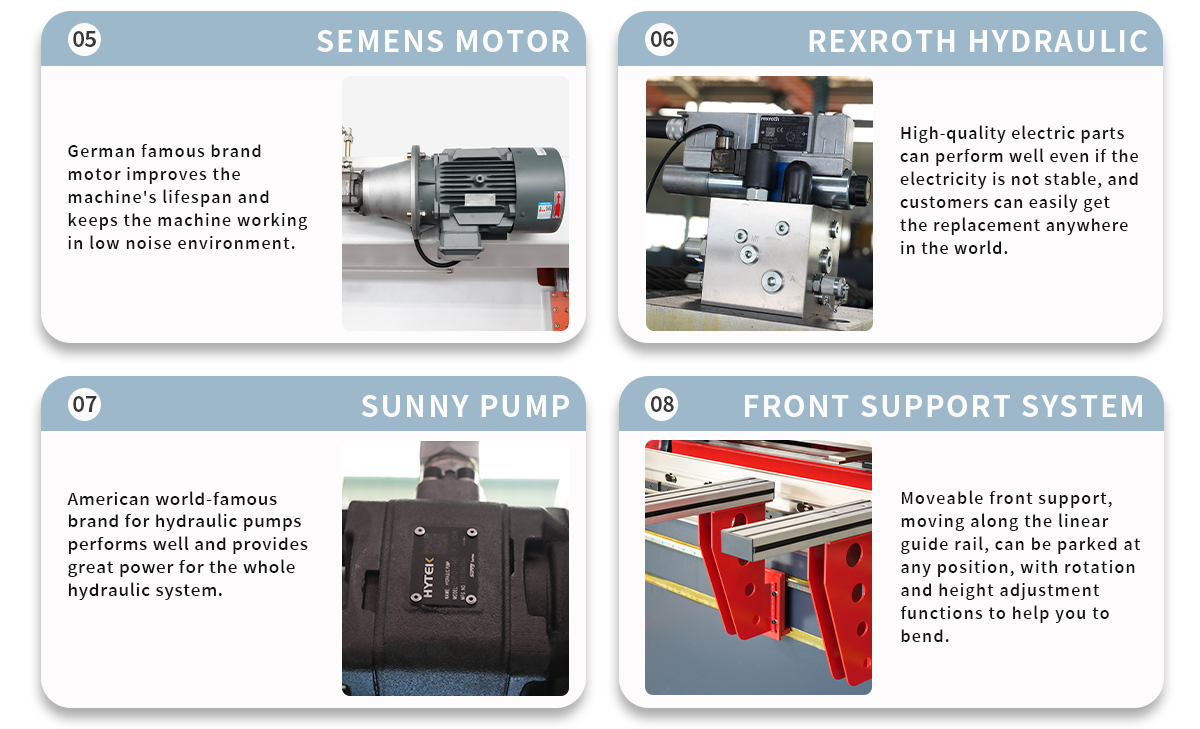

- THE HYDRAULIC SYSTEM ADOPTS THE INTEGRATED CONTROL SYSTEM IMPORTED FROM GERMANY, WHICH REDUCES THE INSTALLATION OF PIPELINES, ENSURES THE STABILITY OF THE MACHINE, AND THE APPEARANCE IS SIMPLE AND BEAUTIFUL.

- C-TYPE PLATES ARE INSTALLED ON BOTH SIDES OF THE MACHINE FRAME, AND THE HIGH-PRECISION GRATING RULER IS MOUNTED ON THE C-TYPE PLATE SO AS TO AVOID THE INFLUENCE OF DEFORMATION OF THE FUSELAGE ON THE BENDING ACCURACY DURING BENDING.

- AUTOMATIC MECHANICAL CROWING MECHANISM ELIMINATE THE INFLUENCE OF SLIDER DEFORMATION ON WORKPIECE QUALITY. CNC CONTROLLER AUTOMATICALLY ADJUSTS THE COMPENSATION AMOUNT, AND THE OPERATION IS CONVENIENT AND ACCURATE.

- SPECIAL CNC CONTROLLER NORMALLY USES HOLLAND DELEM, ITALY ESA, SWISS CYBELEC.

| Type( WE67K series) | Nominal Force (KN) | Bending Length (mm) | Poles distance(mm) | Throat Depth(mm) | Slider Travel(mm) | Die Loading Height(mm) | Main Motor Power(kw) | Axes | Compensation cylinders |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 4+1 | 2 |

| 80T/3200 | 800 | 3200 | 2700 | 350 | 170 | 380 | 7.5 | 4+1 | 3 |

| 100T/3200 | 100 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | 4+1 | 3 |

| 160T/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | 4+1 | 3 |

| 200T/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 250T/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | 4+1 | 3 |

| 320T/3200 | 3200 | 3200 | 2700 | 400 | 200 | 420 | 22 | 4+1 | 3 |

| 400T/4000 | 4000 | 4000 | 3500 | 400 | 320 | 420 | 30 | 4+1 | Mechanical |

| 500T/5000 | 5000 | 5000 | 3900 | 500 | 320 | 600 | 37 | 4+1 | Mechanical |

| 600t/5000 | 6000 | 5000 | 3900 | 500 | 320 | 600 | 45 | 4+1 | Mechanical |