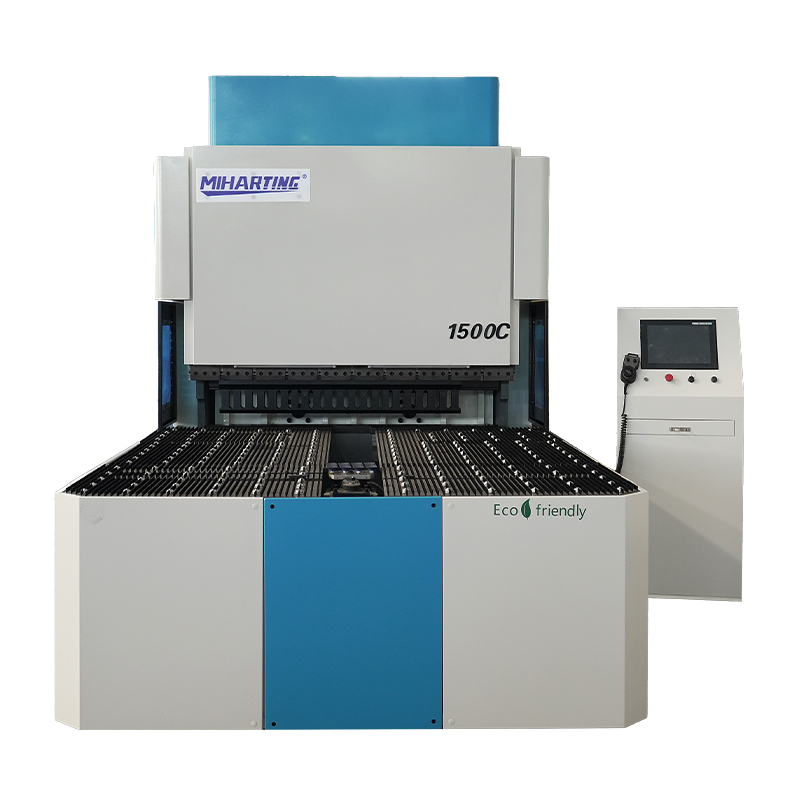

PRODUCT DETAIL

*The control system realizes 13-axis simultaneous linkage in the true sense, smooth bending action, and high coordination of mechanical operation;

*Eccentric load detection system can effectively protect the machine to protect the workpiece;

*The plate thickness detection system can effectively protect the machine and reduce the waste of workpieces;

*The cloud operation and maintenance management system can monitor the operation of the machine in real time;

*For workpieces with non-standard sizes, different positioning datums can be selected according to the shape of the workpiece, and the shearing error of the plate can be controlled on the first bending edge to ensure the accuracy of the size after forming.

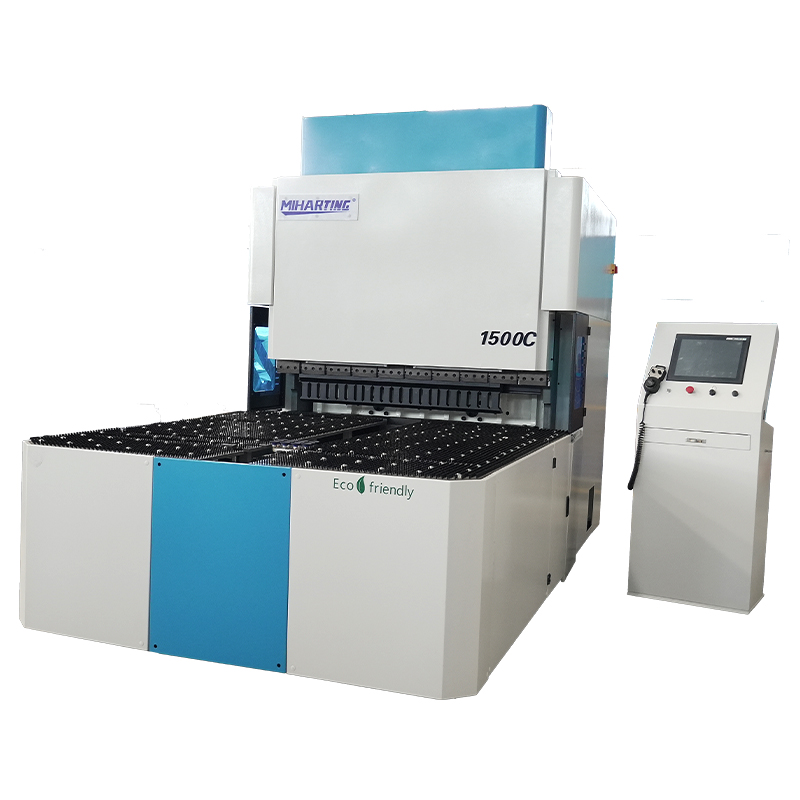

Robot arm description:

The self-driving manipulator of the bending system is adopted, which has high efficiency. It is only necessary to edit the bending program to replace the workpiece. After the bending program is compiled, the corresponding manipulator program is automatically generated. It can be easily connected to upstream and downstream production lines or equipment. The self-driving robot arm used:

The arm span is 2.5 meters, 50KG class, and the workpiece length is within 2000mmX1000mm & the weight of the workpiece is within 25KG. 2 automatic loading and unloading robotic arms.

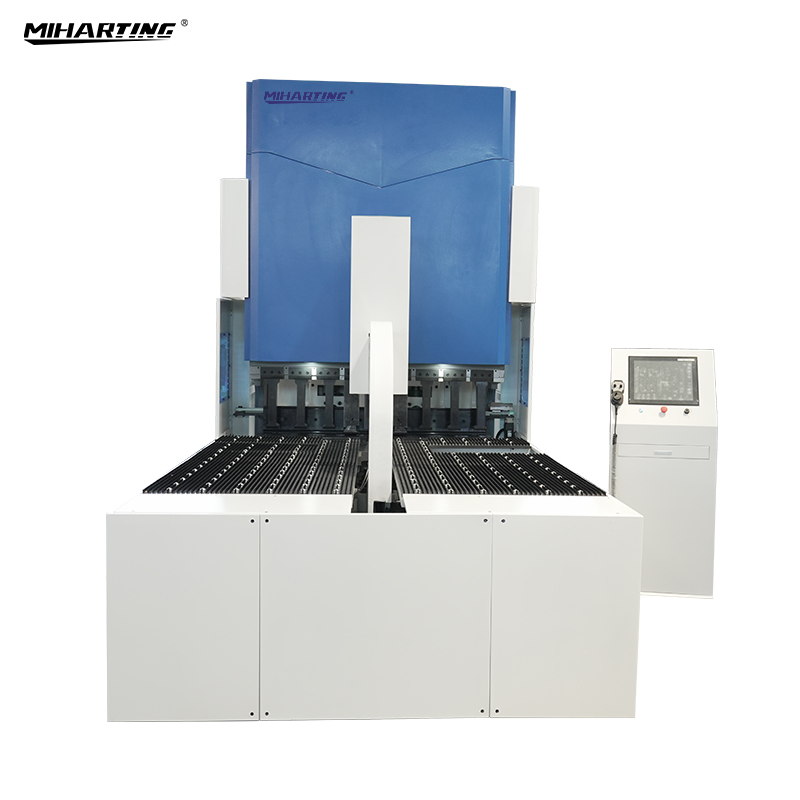

| System min.accuracy | 0.001mm |

| Max. bending speed | 0.2 seconds/knife |

| Max.bending width | 2500mm |

| Max.bending size | Length 2500X width 1250mm |

| Bending height | 170mm |

| The rated voltage | 380V |

| The Peak power | 28KW |

| The Average power | 2.8KW |

| The noise | 50 db |

| Overall dimensions | 565cm X 300cm X 340cm |

| Weight | 19 Ton |

| The operating system | System above Win7 |

| Max. Bending Thickness | Stainless Steel 1.2mm |

| Cold Board 2.0mm | |

| Aluminum board 1.6mm | |

| Min.Thickness | 0.35mm |

| Min. inside size for quad forming | 110mmx200mm |

| Min.inside size for bilateral forming | 110mm |

| Min.arc radius | 1.2mm |

| Bending Angle | 0-180° |

| Number of shaft | 13 |