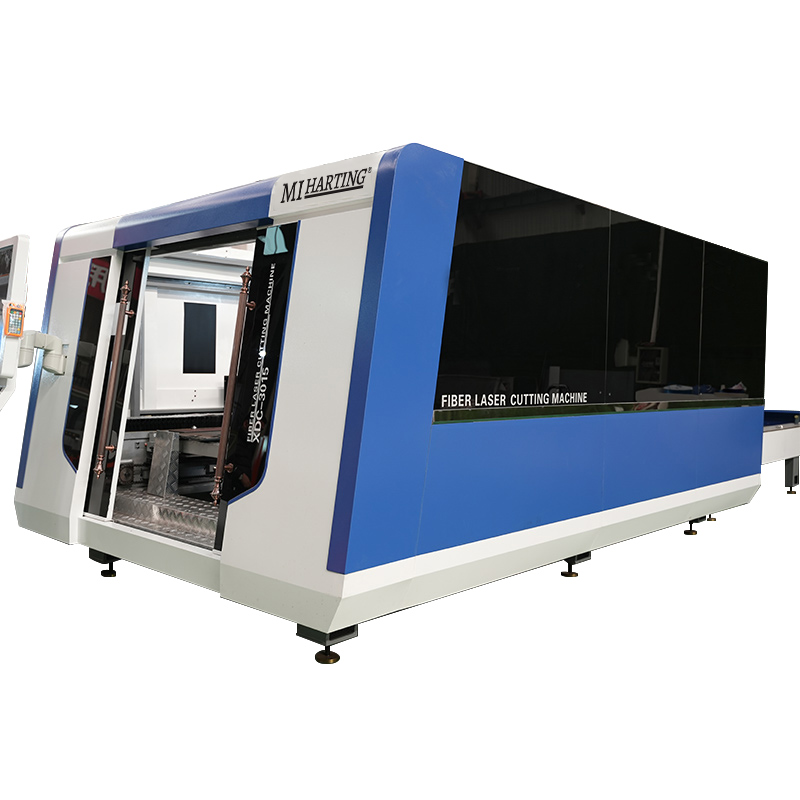

| Model | Harting-LS-3015C | Harting-LS-4015C | Harting-LS-4020C | Harting-LS-6015C | Harting-LS-6020C | Harting-LS-6025C |

| Machining range | 3000mm*1500mm | 4000mm*1500mm | 4000mm*2000mm | 6000mm*1500mm | 6000mm*2000mm | 6000mm*2500mm |

| X-axis stroke | 3000mm | 4000mm | 4000mm | 6000mm | 6000mm | 6000mm |

| Y-axis stroke | 1500mm | 1500mm | 2000mm | 1500mm | 2000mm | 2500mm |

| Z-axis stroke | 120mm | 120mm | 120mm | 120mm | 120mm | 120mm |

| X/Y axis positioning accuracy | ≤±0.03mm/m | ≤±0.03mm/m | ≤±0.03mm/m | ≤±0.03mm/m | ≤±0.03mm/m | ≤±0.03mm/m |

| X/Y axis repeated positioning accuracy | ≤±0.02mm/m | ≤±0.02mm/m | ≤±0.02mm/m | ≤±0.02mm/m | ≤±0.02mm/m | ≤±0.02mm/m |

| Maximum positioning speed | 120m/min | 120m/min | 120m/min | 120m/min | 120m/min | 120m/min |

| Maximum acceleration | 1.0G | 1.0G | 1.0G | 1.0G | 1.0G | 1.0G |

| Maximum load of workbench | 1500kg | 1500kg | 1500kg | 1500kg | 1500kg | 1500kg |

| Machine weight | 4000kg | 4200kg | 5300kg | 5300kg | 7200kg | 8000kg |

| Transmission system | Gantry double drive | Gantry double drive | Gantry double drive | Gantry double drive | Gantry double drive | Gantry double drive |

| Digital control system | Cypcut | Cypcut | Cypcut | Cypcut | Cypcut | Cypcut |

| Dimension | 5000mm*2530mm*2000mm | 6200mm*2530mm*2000mm | 6200mm*3400mm*2000mm | 8500mm*2530mm*2000mm | 8500mm*3400mm*2000mm | 8500mm*3600mm*2000mm |

Specification

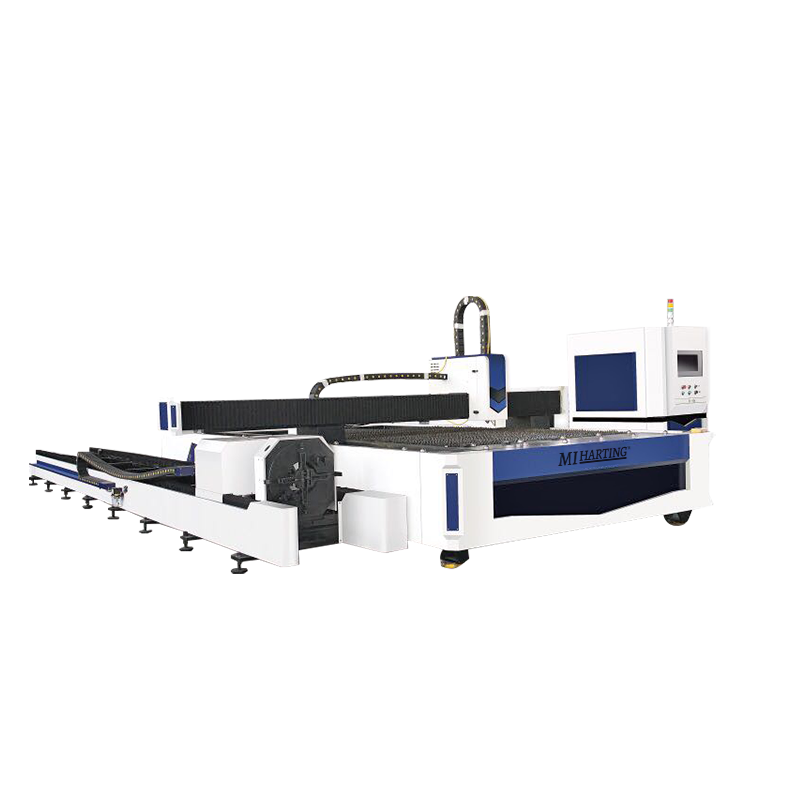

| Equipment Specification | |||||

| Model | 3015H | 4015H | 6015H | 4020H | 6020H |

| Cutting Area | 3000*1500mm | 4000*1500mm | 6000*1500mm | 4000*2000mm | 6000*2000mm |

| Laser source | MAX | MAX | MAX | MAX | MAX |

| Max Moving Speed | 100m/min,Acc=1.0G | 100m/min,Acc=1.0G | 100m/min,Acc=1.0G | 100m/min,Acc=1.0G | 100m/min,Acc=1.0G |

| Position Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Reposition Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Power | 380V 50/60Hz 50A | 380V 50/60Hz 50A | 380V 50/60Hz 50A | 380V 50/60Hz 50A | 380V 50/60Hz 50A |

| Max Loading(KG) | ≤4000 | ≤5000 | ≤5500 | ≤6000 | ≤6000 |

Cutting parameters:

| Material | Thickness/mm | 1000W m/min | 1500W m/min | 2000W m/min | 3000Wm/min | 4000W m/min | 6000W m/min |

| Stainless steel | 1 | 18-20 | 25-30 | 25-35 | 25-40 | 30-54 | 30-60 |

| 2 | 5--6 | 8--10 | 10--12 | 18-20 | 18-24 | 30-36 | |

| 3 | 2.8-3.5 | 4-4.5 | 4--6 | 8--10 | 10--15 | 15-20 | |

| 4 | 1.2-1.5 | 1.5-1.7 | 2.8-3.2 | 2.9-4 | 7--8 | 11--14 | |

| 5 | 0.8-1.0 | 1.6-2 | 3--4 | 5-5.5 | 7--8 | ||

| 6 | 1-1.2 | 2.2-3 | 3.6-4 | 5--6 | |||

| 8 | 0.5-0.6 | 1.2-1.5 | 1.5-2 | 3.8-4.2 | |||

| 10 | 0.5-0.8 | 1.2-1.5 | 1.8-2.2 | ||||

| 12 | 0.8-0.85 | 1.2-1.5 | |||||

| 14 | 0.9-1 | ||||||

| 16 | 0.65-0.75 | ||||||

| Carbon steel | 1 | 14-16 | 22-24 | 20-25 | 25-30 | 35-40 | 40-50 |

| 3 | 3.4-3.7 | 3.6-3.8 | 4-4.2 | 3.5-4.5 | 4.2-4.5 | 4-4.5 | |

| 6 | 1.5-1.8 | 1.5-1.8 | 2.5-3 | 2.2-2.8 | 2.5-3 | 2.8-3.4 | |

| 8 | 1-1.3 | 1.2-1.3 | 1.2-1.5 | 1.6-2 | 2.4-2.8 | 2.5-2.8 | |

| 10 | 0.8-0.9 | 1.0-1.1 | 1-1.2 | 1.1-1.4 | 1.8-2.1 | 1.4-2.2 | |

| 12 | 0.8-1.0 | 0.9-1 | 0.9-1.1 | 1.2-1.4 | 0.9-1.8 | ||

| 14 | 0.5-0.7 | 0.7-0.8 | 0.8-0.9 | 0.9-1 | 0.8-1.3 | ||

| 16 | 0.7-0.8 | 0.7-0.8 | 0.7-1 | ||||

| 18 | 0.65-0.7 | 0.65-0.7 | 0.65-0.75 | ||||

| 20 | 0.55-0.65 | 0.55-0.65 | 0.6-0.7 | ||||

| 22 | 0.5-0.55 | 0.55-0.65 |