Author's Credentials:

With over a decade of experience in the steel industry, I have witnessed firsthand the transformative power of steel bending machines. This guide will delve into the multifaceted advantages and applications of these remarkable machines, empowering you to make informed decisions.

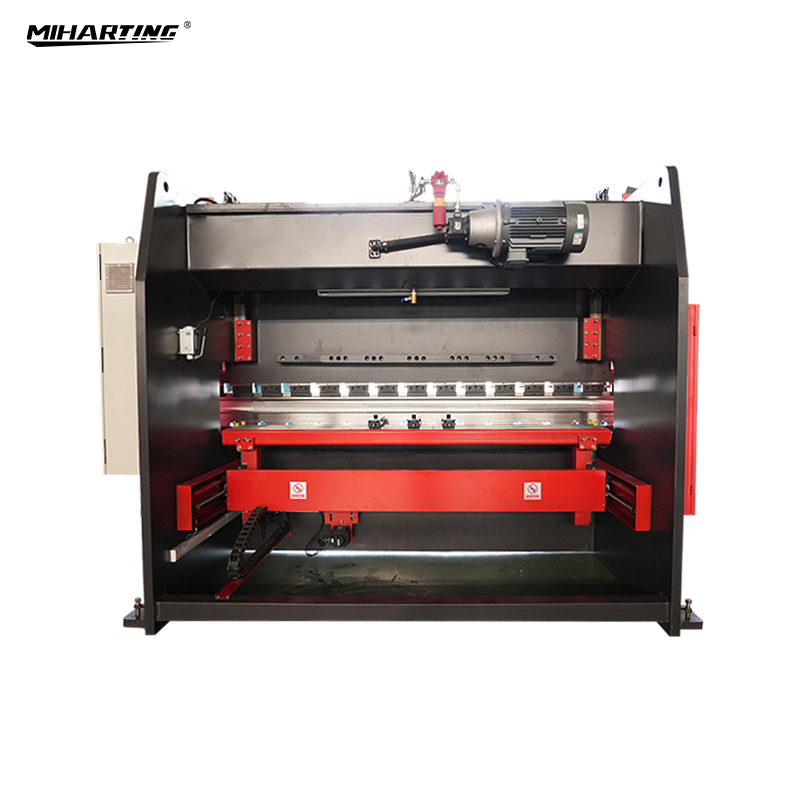

Unveiling the Steel Bending Machine

Steel bending machines, also known as press brakes, are indispensable tools for shaping and forming steel sheets into complex geometries. Their primary function is to apply precise force along a predetermined axis, enabling the creation of angles, curves, and other intricate shapes.

Types of Steel Bending Machines

The versatility of steel bending machines is reflected in their diverse types, each tailored to specific applications:

- Mechanical Press Brakes: Utilizing a mechanical flywheel to generate immense force, these machines are ideal for heavy-duty bending operations.

- Hydraulic Press Brakes: Powered by hydraulic cylinders, these machines offer precise control and smooth bending motions.

- CNC Press Brakes: Integrated with computer numerical control systems, CNC press brakes provide unparalleled accuracy and automation capabilities.

Advantages of Steel Bending Machines

The allure of steel bending machines lies in their numerous advantages:

Precision and Repeatability

These machines enable intricate bending operations with remarkable precision, ensuring consistent results every time.

Time Savings

Automating the bending process through steel bending machines significantly reduces production time, freeing up labor for other tasks.

Versatile Applications

From intricate automotive parts to complex architectural elements, steel bending machines cater to a wide spectrum of industries.

Increased Productivity

Streamlining the bending process with automated machines enhances productivity and streamlines operations.

Features of Steel Bending Machines

Beyond their advantages, steel bending machines boast an array of features that elevate their performance:

Adjustable Bending Angle

The machines offer adjustable bending angles, allowing for customization to suit specific requirements.

Backgauge and Clamping Mechanisms

Precision backgauges and clamping mechanisms ensure accurate positioning and secure holding of the workpiece.

Hydraulic Power Systems

Hydraulic systems deliver smooth, controlled, and powerful bending operations, ensuring consistent performance.

Safety Features

Industry-leading safety protocols, such as emergency stop buttons and light curtains, safeguard operators during operation.

Experiential Sharing: Tales of Transformation

Real-world experiences paint a vivid picture of the transformative power of steel bending machines:

A Fortune 500 Automotive Manufacturer: Leveraging CNC press brakes, they achieved a 30% increase in productivity, enabling the mass production of complex automotive parts.

A Renowned Architecture Firm: Collaborating with steel bending machine experts, they engineered intricate architectural facades, bringing their visionary designs to life.

A Start-up Aerospace Company: Utilizing mechanical press brakes, they created custom-engineered components for their innovative aircraft designs.

Tips and Suggestions for Success

Maximizing the performance of steel bending machines demands careful consideration:

- Invest in high-quality machines from reputable manufacturers.

- Ensure proper maintenance and lubrication to prolong the machine's lifespan.

- Train operators thoroughly on safe and efficient operation.

- Utilize digital technology to optimize machine settings and streamline the bending process.

Industry Insights: Unveiling the Market Landscape

According to a report by Grand View Research, the global steel bending machine market is projected to reach $2.2 billion by 2027, highlighting the growing demand for these machines across industries.

Steel Bending Machine for Sale: Embracing the Possibilities

The purchase of a steel bending machine is an investment in innovation and efficiency. Consider the following factors when making your selection:

- Determine the specific bending needs of your application.

- Evaluate the capacity, features, and safety certifications of different models.

- Seek expert advice from industry professionals or reputable distributors.

Frequently Asked Questions: Empowering Knowledge

Q: What is the difference between mechanical and hydraulic press brakes?

A: Mechanical press brakes utilize a flywheel for rapid bending, while hydraulic press brakes use hydraulic cylinders for more controlled and precise operation.

Q: How can I ensure the accuracy of bending operations?

A: Employing precision backgauges and utilizing CNC technology enables highly accurate bending, minimizing errors.

Q: What safety measures should I prioritize?

A: Ensure the machine is equipped with emergency stop buttons, light curtains, and proper guarding to protect operators.

Conclusion: A Gateway to Bending Innovation

Steel bending machines for sale empower businesses of all sizes to unlock the full potential of steel. Their unparalleled accuracy, versatility, and efficiency drive productivity, innovation, and the creation of extraordinary products. Embracing these remarkable machines is the key to shaping a future filled with precision and possibility.